|

|

|

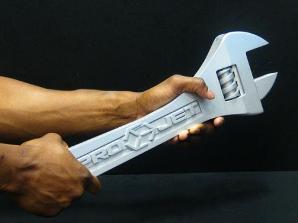

Rapid Prototyping...

We are currently looking at 3-axis and 5 axis robotic and laser rapid prototyping fabrication facilities to enable the

scanning and production of parts for our Research & Development. These facilities are complementary to the heavier engineering fabrication workshops. One half of the facilities will focus on the laser lithography and rapid prototyping using specialist plastics,

resins and styrenes to produce models and parts for our work. Below are some of the suppliers' examples of the types of

products that can be designed and fabricated rapidly using these systems. The first two are fairly obvious working and highly

robust prototypes - the last picture is of the intricate parts and structures of a human heart... The other

half will be the rapid milling and handling of the special metals we use for certain parts (mostly for copper and aluminium

aerospace-grade alloys) - part of these facilities will be able to handle the more hazardous metals that require careful

machining such as beryllium and magnesium. More about these facilities will follow....

Enter content here Enter content here Enter content here |

AREA17: World Class Rapid Prototyping - what do you want and how many...